Phase 5.

Process Optimization and Quality Assurance

Phase 1.

A Comprehensive Evaluations of the Production Workflows

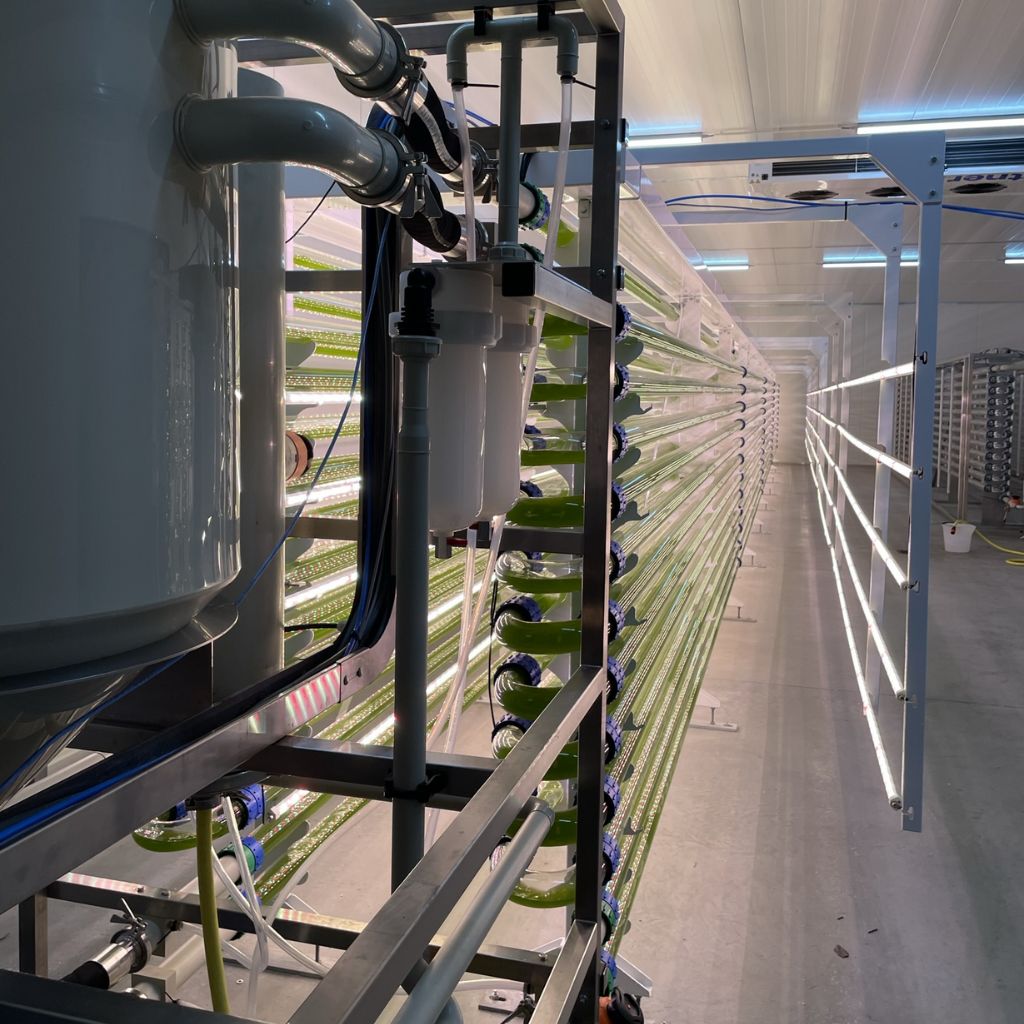

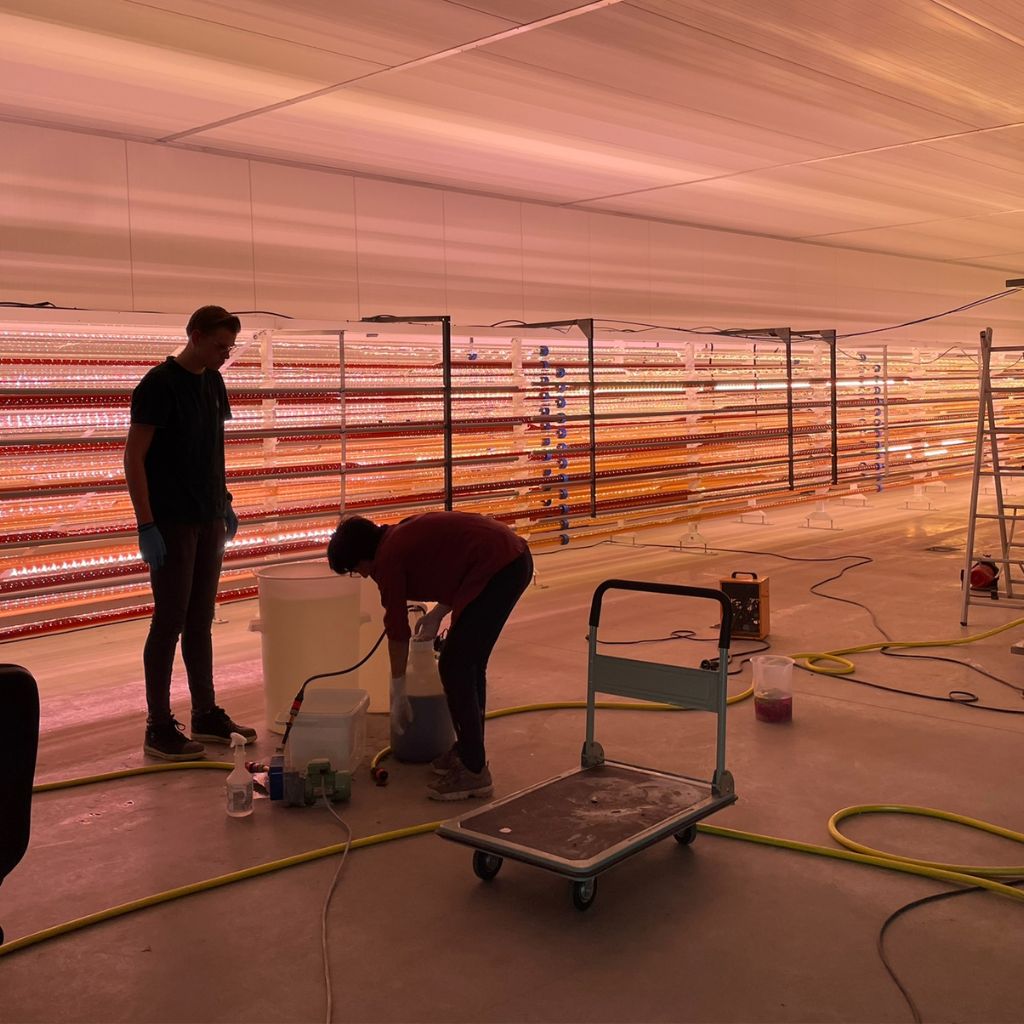

Phase 5 of the AlgaeHUB expansion focuses on process optimization and quality assurance. This phase is important for ensuring the efficiency and consistency of production workflows in the microalgae production process.

During this phase, comprehensive evaluations of the production workflows are conducted to identify areas for improvement. The goal is to streamline processes, eliminate bottlenecks, and maximize productivity. Through careful analysis and data-driven insights, adjustments and enhancements are made to optimize resource utilization, minimize waste, and enhance overall efficiency.

Quality assurance measures are of paramount importance in the AlgaeHUB expansion. Strict protocols and standards are implemented to guarantee consistent and reliable results. This includes rigorous quality control checks at various stages of the production process to ensure that the desired specifications and parameters are met.

The implementation of robust quality assurance measures

Continuous monitoring and analysis of key performance indicators enable proactive identification and mitigation of any deviations or potential issues, ensuring the highest levels of quality.

The implementation of robust quality assurance measures includes the use of advanced technologies, standard operating procedures and a highly skilled and trained workforce. Regular audits, software implementation, inspections, and certifications further validate the adherence to quality standards and regulatory requirements.

By focusing on process optimization and quality assurance, the AlgaeHUB expansion ensures the delivery of high-quality products and services to its customers. This phase lays the foundation for consistent and efficient production, further reinforcing the reputation of the Lgem as a trusted and reliable provider in the field of algae cultivation and research.