Our photobioreactors

We proudly present our innovative technologies, the best in today’s market, meeting all requirements of modern demand.

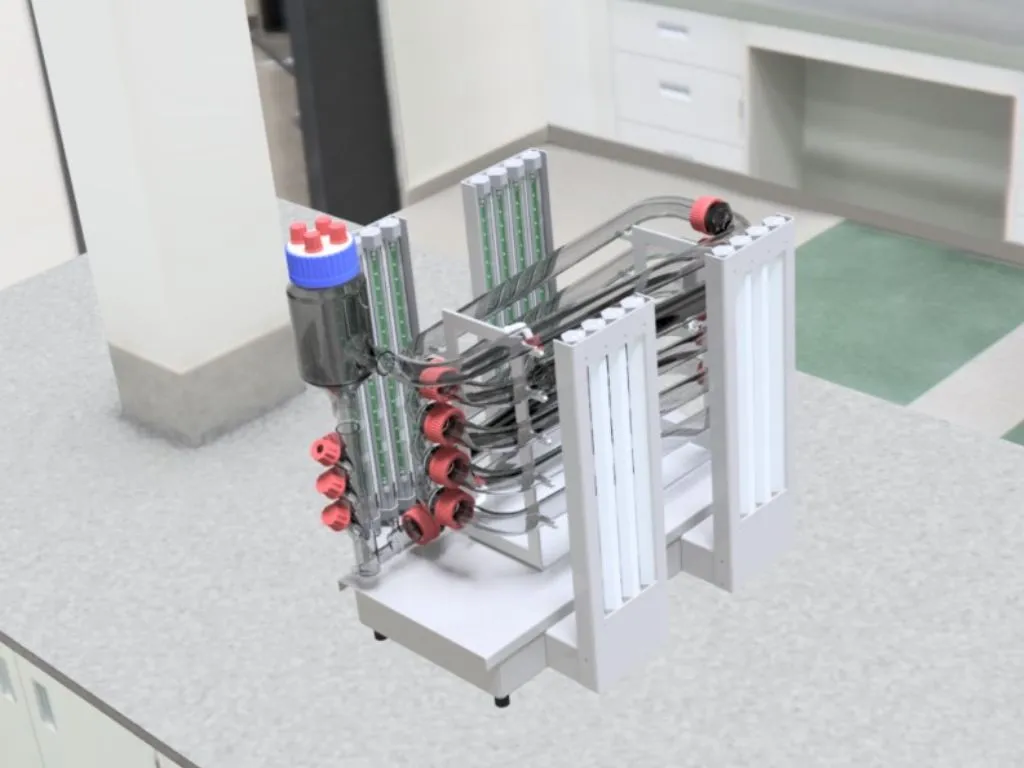

NEW: Lab-5

A 3-liter Benchtop System

Lgem introduces its unique and innovative 5-liter benchtop system, catering to the entire algae cultivation supply chain, from research and startups to large-scale industrial production. The highly customizable 5L system, founded on the seed train methodology, offers an even lower entry level into algae cultivation, enabling researchers and startups to easily explore, initiate and optimize their algae cultivation.

Streamlining Production for Lgem PBRs

The process by which we generate complex algae systems.

Lgem PBRs are crafted in a nearby factory, guaranteeing top industry standards. With advanced automation and skilled operators, we deliver our full product range with the finest quality, utilizing cutting-edge tools and systems. The nearby factory enables us to safely outsource production of our solutions with the highest industry standards (e.g. industry 4.0) in mind.

The high levels of automation and the trained skilled personnel produces our complex systems with the highest quality , the latest production tools and the best systems.

1. Production

At this state of the art, highly automated production facility, our Lgem PBRs are put into production via an automated process.

2. Strength checks

Starting with a program that first carries out several checks on flow and strength in order to guarantee a perfect design. Followed by the Tube lasercutter and robotised bendingcells which receive the Lgem technical drawings through a fully automated workflow process.

3. Fabricate frames

These machines then fabricate different parts to construct (TIG welding) the frame for the PBRs.

4. fulfilment and logistics

This frame together with the glass, pumps, filters, sensors and other parts are assembled, checked and tested by a highly skilled team. All our PBRs are tested at our facility before they are shipped all over the world.

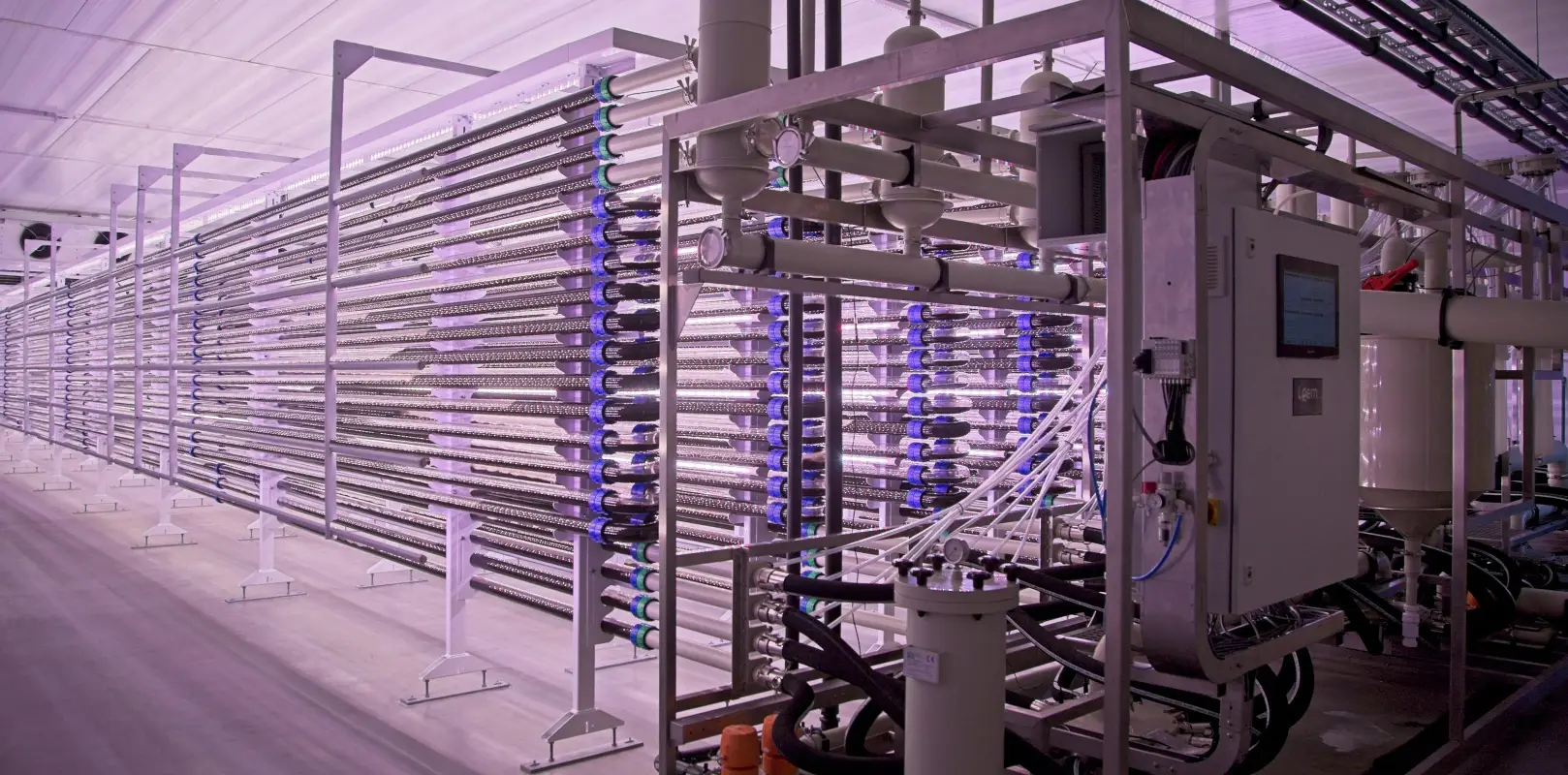

Lgem introduces advanced microalgae cultivation. Explore a transformative approach to automation, optimising every step of the process. Discover the innovative use of light, CO2, and nutrients in our tubular photobioreactors, and gain insight into integrated upstream and downstream techniques that streamline production for superior results.

Automation

Streamline your production facility with Lgem’s MPCC

AI modules aid in faster process improvements and higher yields. Lgem systems are fully automated and seamlessly integrated into an upstream and downstream process. This makes cultivating algae effortless.

The Microalgae Production Control Computer (MPCC) offers you a clear overview of the performance of the different processes. It also allows you to make changes or troubleshoot in operation. It fully complies with state-of-the-art industrial components (industry 4.0 ready) and ensures fast performance and reliability.

Light

Lgem PBR’s have a high conversion from LED light to biomass.

Lgem’s tubular photobioreactors use light, CO2 and nutrients for the cultivation of microalgae through the process of photosynthesis.

Our systems convert light efficiently into biomass, a true success factor for commercial algae production. With LED, this can be done under stable and optimised conditions. This results in higher yields as well as a better quality.

Up- and downstream

Technologies completing your production

Lgem can deliver completely automated production facilities with integrated upstream and downstream unit operations.

Upstream, we offer our in-house developed clean water unit and nutrient dosing unit.

Downstream, we have numerous solutions depending on the algae species and market application. For instance, microfiltration or even ultrafiltration is possible for preconcentration, followed by centrifugation.

Applications

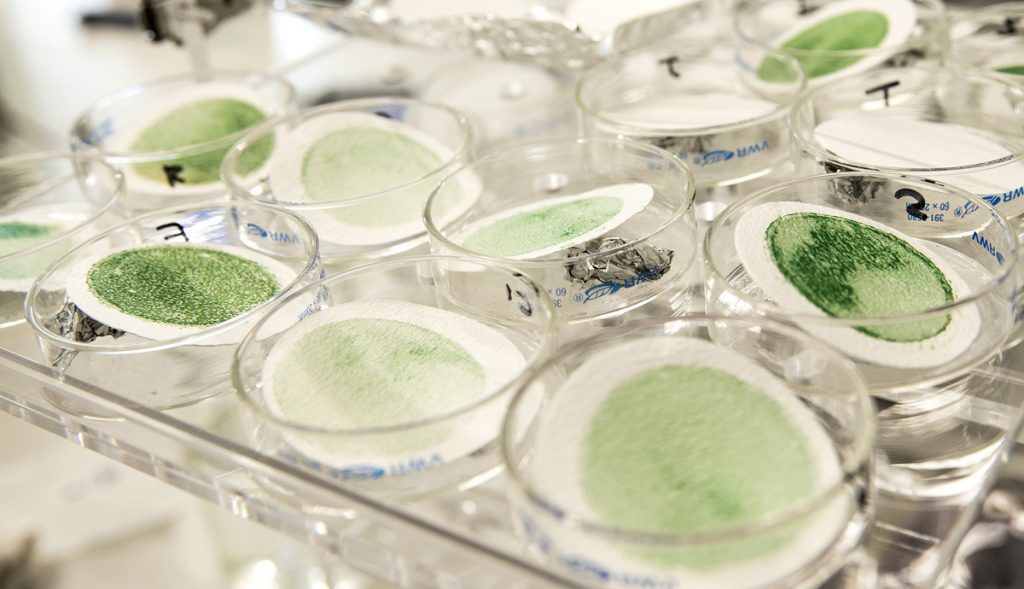

Algae are indispensable

Algae form the fundamental component of food chains in global ecosystems. Microalgae are of significant impact and need to be nurtured and cultivated to unlock their full potential. They are precious, yet affordable.

Food and nutrition

Enhancing the nutritional value of food and animal feed

Algae are the primary provider of unique molecules that play an essential role in our food chain. They are an indispensable source of these ingredients. Algae can ensure sustainable and efficient supply chains for a better future – without compromising quality and nutritional value.

Biotechnology

Valuable products from biotechnology of microalgae

Many industries already use high-value algae products, most notably food, cosmetics, nutraceuticals and pharma. Examples of ingredients include Phycocyanin (blue food colouring pigment), Astaxanthin (powerful red antioxidant for nutraceuticals, aquaculture and pharma), B-Carotene (orange antioxidant for nutraceuticals) and EPA/DHA (fish free long-chain Omega-3-unsaturated fatty acids).

Health

Unlocking the health potential of microalgae

An increasing amount of research concludes that algae are the number one producer of healthy natural ingredients. Still, most of our medicine stems from terrestrial plants. Algae are more abundant, have more diverse compositions and levels of active compounds. They have protein levels similar to meat and fatty acid profiles like fresh fish; all in all, they are healthier than any other food we consume.

In our AlgaeHUB® we demonstrate and share the full experience of our newest algae technologies. Test and try, a must-have for any scale-up.

Technology partners

We pride ourselves in our partnerships, and together we can go to the next level.