The Expansion of the AlgaeHUB®

by Lgem

Phase 1.

AlgaeHUB 2.0

Welcome to the AlgaeHUB e-magazine! In this magazine, we aim to inform you about the exciting expansion of AlgaeHUB. We are thrilled to take you on a journey where we show how we realized our vision. Our main goal of the expansion is to support your needs with our upgraded AlgaeHUB® services.

Lgem

We believe that algae are the answer to some of the greatest global challenges. Algae are becoming a dominant source of sustainable solutions, while applications are virtually endless. However, lack of industrial scalability creates a critical barrier to their immense potential. Questions about cost, quality, skilled labour, risk and productivity pose significant threats for further investments. Our approach at the AlgaeHUB proves that algae production can be done successfully and sustainably on an industrial scale. The scalable Lgem systems and genuine de-risking services have been the missing link in our industry.

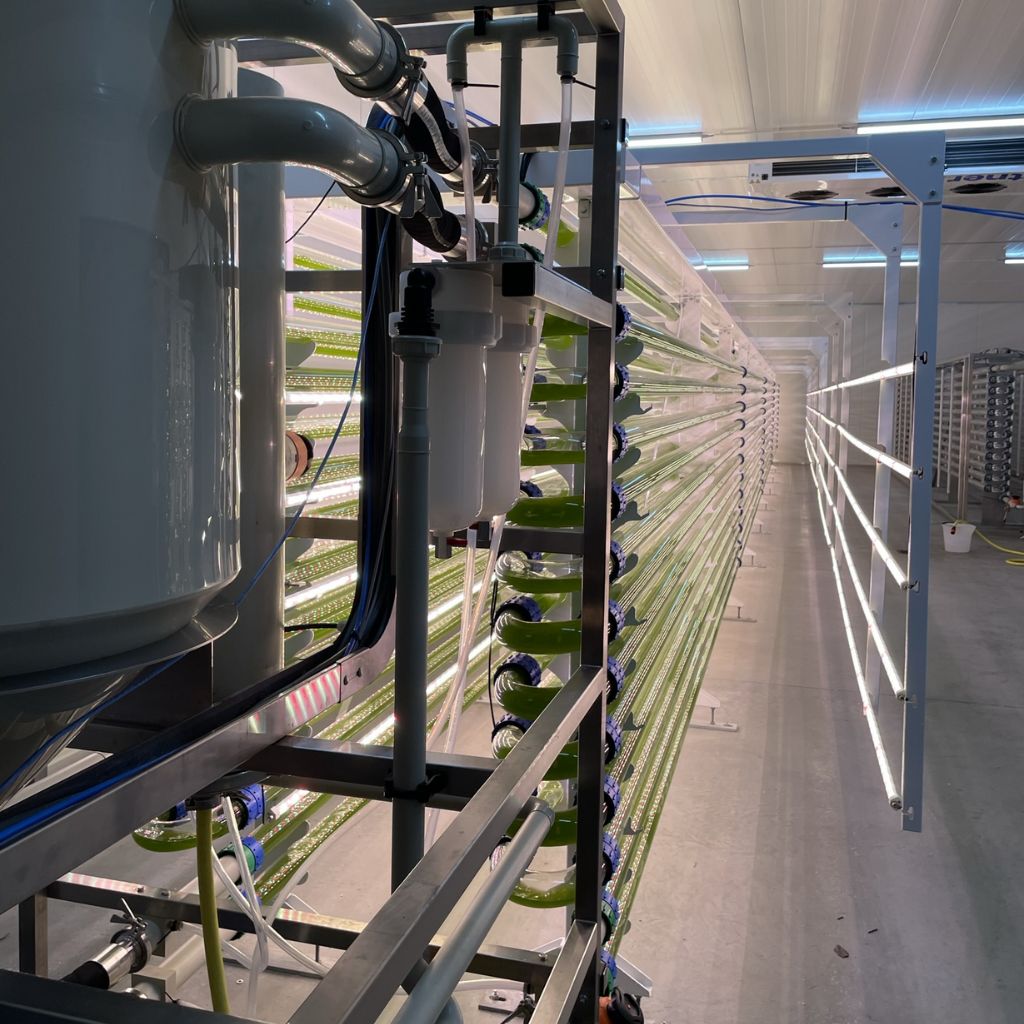

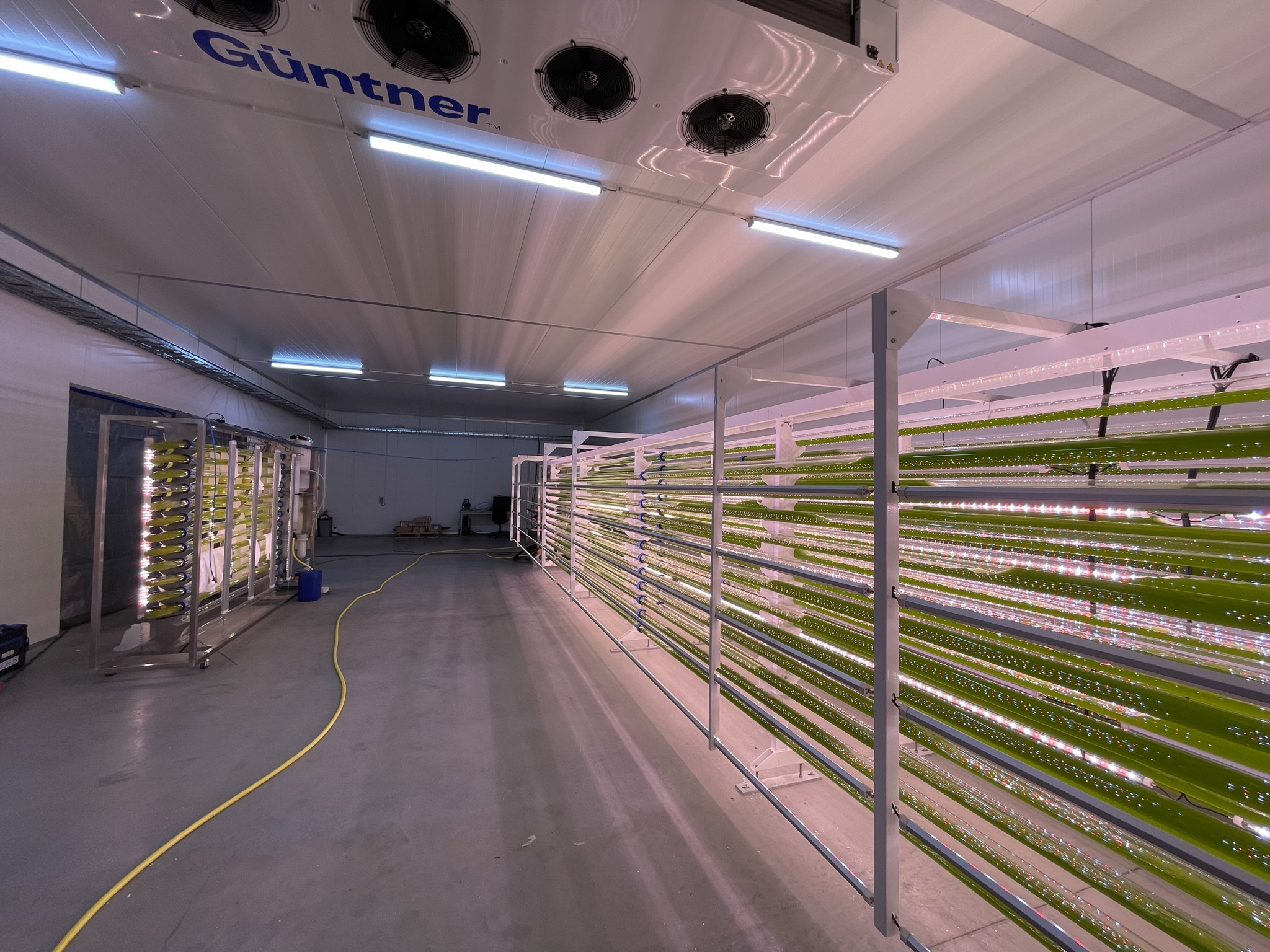

AlgaeHUB®

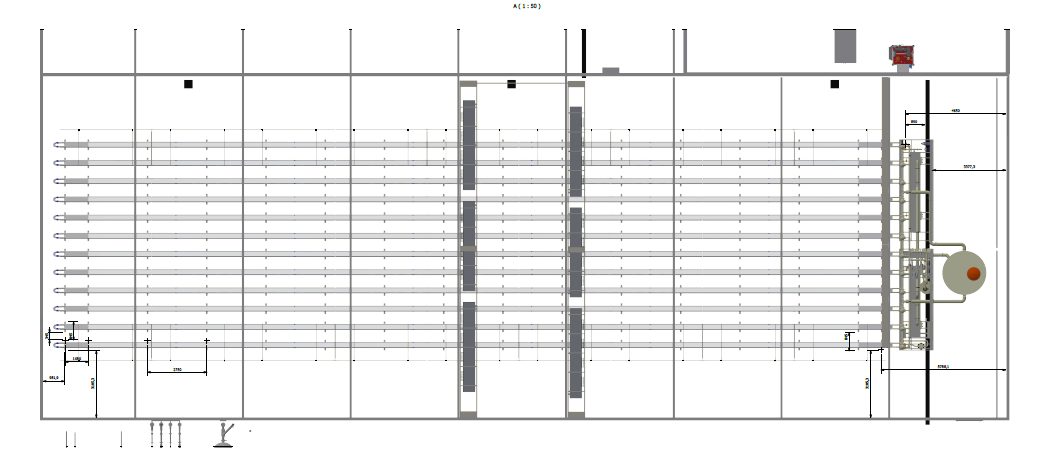

We present our reliable and easy-to-use systems to produce microalgae at our cutting-edge AlgaeHUB®. In our completely unique 8000 m² facility near Amsterdam Schiphol Airport, we offer our latest technologies. The Lgem assortment ranges from 5 litre to modular production units for industrial production facilities for inside, outside and greenhouse solutions. At the AlgaeHUB® we have our product portfolio available with a tema of scientists to develop and optimize your microalgae driven production process. Along the way we obtain insights in sizes of unit operations required for your facility. De-risking allows validation of your business case on a commercially relevant scale. Our R&D services offer ground-breaking possibilities, solutions, and process improvements.

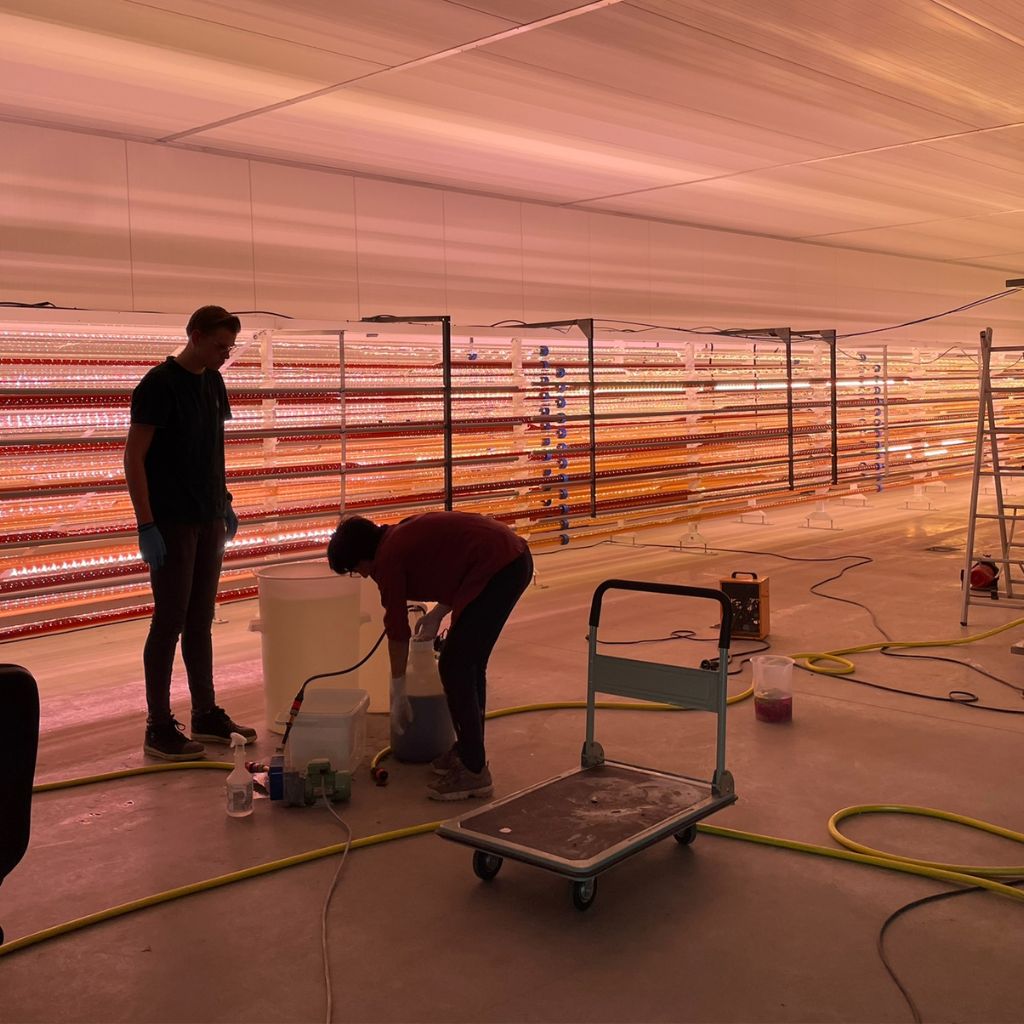

The Expansion

The expansion of AlgaeHUB® has been a result of careful planning and execution. With great enthusiasm, we have worked towards creating an advanced facility that is at the forefront of algae research and production. This e-magazine provides you with a unique opportunity to learn more about the various steps and processes that have contributed to the realisation of our ambitious project. From identifying the needs of our target audience to optimising processes and ensuring quality, we will share the key milestones and achievements with you.