Blog

Fresh Perspectives Revealed. Explore our Latest Insights

Articles

- Algae Biotechnology, Photobioreactors, Research paper

- algae, Algae Biotechnology, algaehub, wastewater

- algae, Algae Biotechnology, algaehub

Research paper: Quantifying the performance of a photobioreactor

Download the Research Paper: Quantifying Photobioreactor Performance Download our research paper, Quantifying the Performance of a Photobioreactor, for practical insights

Optimising Lgem PBR performance for high-density algae cultures

Scaling up algae production to an industrial level presents both opportunities and challenges. Achieving high productivity and consistent yield at

Engineering solutions for microalgae production

In microalgae biotechnology, photobioreactors (PBRs) are indispensable tools, enabling precise control over the cultivation environment to maximize algal growth and

The use of a wastewater stream to grow algae | Lgem

Can you use a wastewater stream to grow algae? At Lgem, we often receive inquiries about growing algae on nutrient-rich

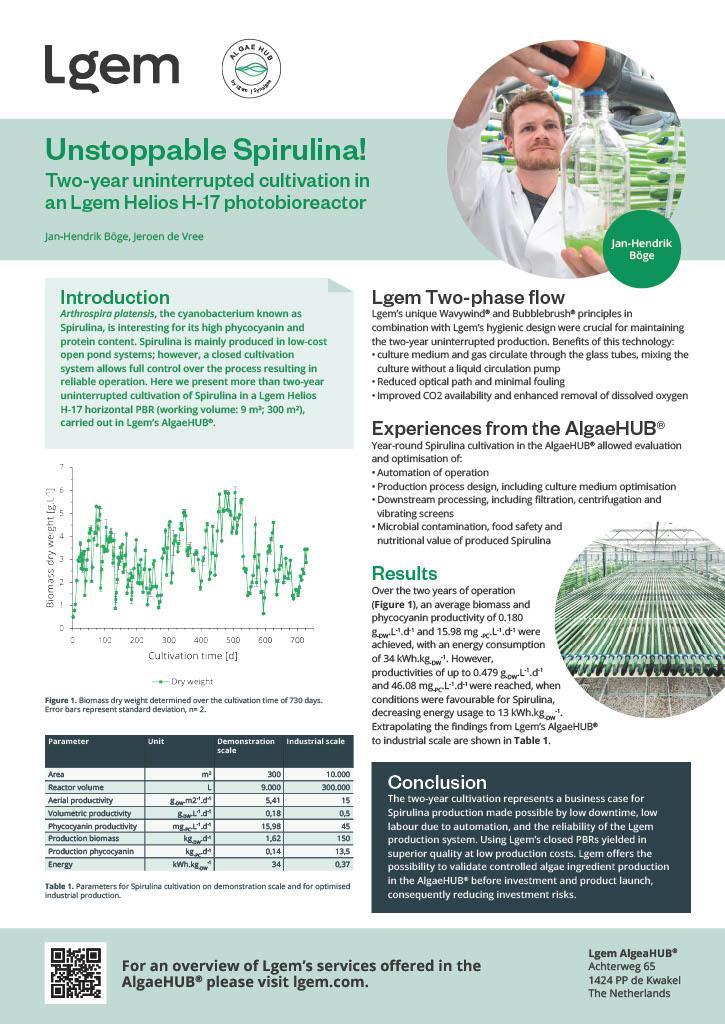

Research paper: Unstoppable Spirulina

Download the Research Paper: Unstoppable Spirulina Lgem’s two-year Spirulina cultivation project at AlgaeHUB® demonstrates the reliability and scalability of its

Marta Batista de Sá, Leads AlgaeHUB® Toward a Sustainable Future in Algae Biotechnology

Algae Biotechnology for Sustainable Innovation. We are excited to introduce Marta Batista de Sá as the new lead of the

Behind the scenes v2food x Lgem

Meet the Architect: CSO Pieter Oostlander shares insights on process at Lgem’s AlgaeHub, focusing on plant-based protein innovations. A revolution

Optimization of microalgae production

Relationship Between Specific Growth Rate, Volumetric Productivity, and Biomass Concentration in Photobioreactors 1. Introduction A photobioreactor is a system that

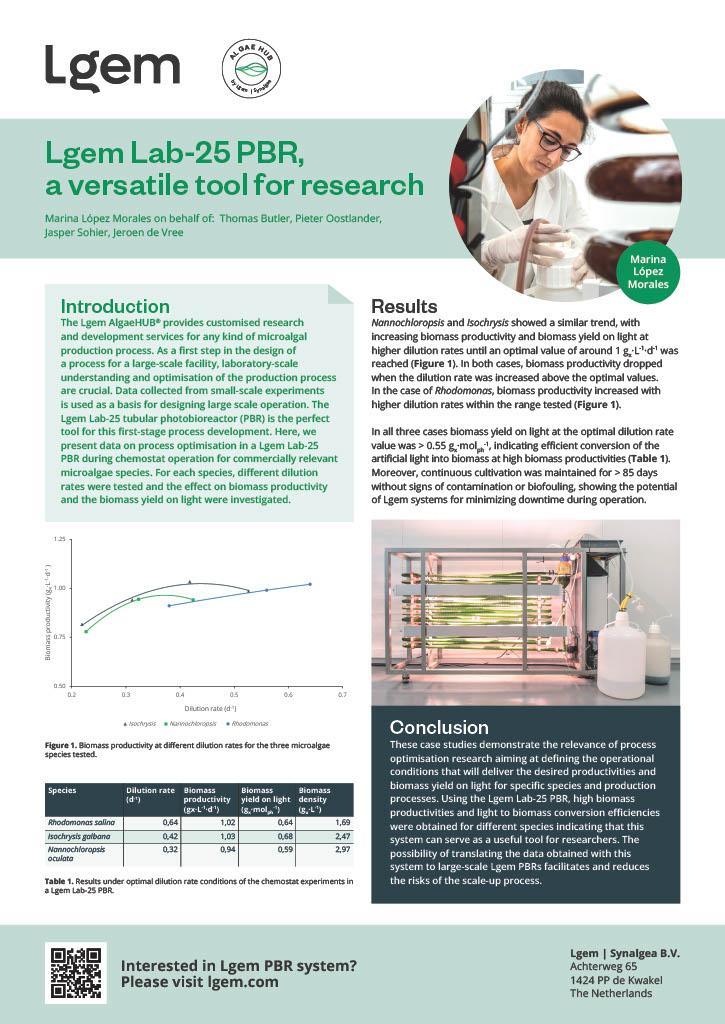

Research paper: Lgem Lab-25 PBR, a versatile tool for research

Download the Research Paper: Lgem Lab-25 PBR, a versatile tool for research The Lgem Lab-25 photobioreactor (PBR) proves to be

Lgem partners with Navus Ventures to drive algae innovation

Dutch scale-up Lgem secures investment from Navus Ventures to accelerate expansion of its innovative two-phase algae technology and AlgaeHUB. Lgem,

Breaking records: setting the hygiene standard with Lgem PBR systems

Are you familiar with the Knowledge section of our brand-new website? Since the launch, we’ve published some interesting insights there.

Algae: the resources of the future

Lgem’s most popular algae strains Algae form the fundamental component of food chains in global ecosystems. They hold a lot

White papers

Explore our White Papers. Practical Insights

Algae cultivation scale-up with Lgem PBRs

Scaling algae cultivation from laboratory conditions to industrial production scale is a complex process that requires careful consideration of biological, technical, and operational factors. This guide provides practical insights into scaling with Lgem’s photobioreactors (PBRs), addressing common challenges and strategies to ensure efficient and stable production at larger scales. 1. Key steps in transitioning from lab-scale to pilot-scale to industrial-scale cultivation Environmental control variations Lab environments offer high control over culture conditions such as temperature, pH, and light and nutrient availability. Scaling up introduces environmental variability, especially in outdoor systems subject to seasonal and daily variations. To mitigate this,

Laboratory Research

Case Study

Exploring the Experiences off our Partners

- case study, nutrition, v2food

- case study, Lab-25, Photanol

Lgem Photobioreactors

Modular and scalable production systems with proven track records and minimal downtime

Expert voices

v2food

- case study, nutrition, v2food

Photanol

- case study, Lab-25, Photanol

Videos

Blog articles

- Algae Biotechnology, Photobioreactors, Research paper

- algae, Algae Biotechnology, algaehub, wastewater

- algae, Algae Biotechnology, algaehub