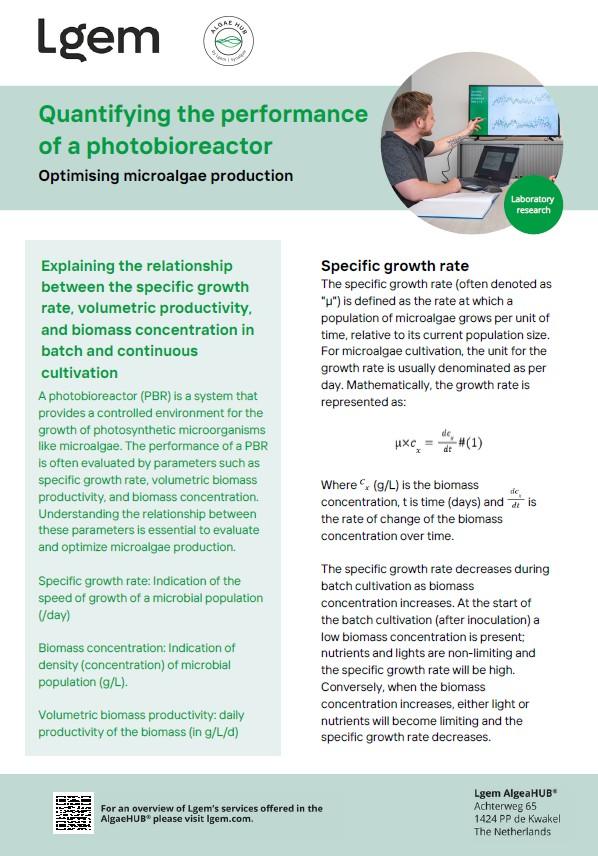

Lgem, founded in 2006, is the first company in the Netherlands to specialise in building patented photobioreactors for microalgae cultivation, using innovative in-house technology such as WavyWind® and Bubblebrush®. “Why Algae?”, asks Sander Hazewinkel, our CCO. “They hold many resources and are fast becoming the go-to commodity for a sustainable future.”

“The omega-3 fatty acid you can extract from algae is used for various purposes. It can serve as food for zooplankton, which are eaten by fish larvae on commercial farms. In margarine, eggs, medicines, and cosmetics, you can also find omega-3-fatty acids. For proper growth, sea bream and bass absolutely need the omega-3 fatty acid as well as the live algae. That’s what makes algae so valuable.”

B2B two-phase photobioreactor technology

Imagine a large greenhouse filled with long glass tubes—huge and technologically advanced installations with stacked glass tubes. Water flows through them in meticulously calculated waves while sunlight shines in to work its magic. Here, algae are produced, cultivated as a protein source, as raw material for medicine, and as input for many other valuable applications. These tubes allow for high-quality algae cultivation for any number of sustainable applications, even in locations whit a sparse water supply.

“Our proprietary PBR or photobioreactor technology was developed, improved and validated at Lgem’s commercial facilities”, says Hazewinkel. “After examining, testing and trying numerous algae production systems, from plastic bags and bubble column to PVC tubes, we’ve launched our own glass tubular helix system. It offers numerous advantages, such as a more simplified, cost-effective form of algae cultivation, as well as extreme durability. It has low operational costs due to low consumption of energy. There’s minimal loss of water, minimal labour, minimal maintenance. You can understand our enthousiam!”

A two-phase flow is created in each tubular loop, resulting in the unique Wavywind® and Bubblebrush® principles. The two-phase flow looks like elongated gas bubbles alternated with liquid slugs, mixing the culture without a liquid circulation pump. “This makes Lgem PBRs uniquely suitable for cultivating fragile and challenging species.”

“To clarify, we do not cultivate algae here”, continues Hazewinkel. “We merely provide the reliable, patented systems necessary to do so on any desired scale. We have over 15 years of hands-on experience building these installations for the Nannochloropsis, Chlorella, Spirulina and many other species of algae. A solid basis of knowledge, development and innovative design puts Lgem at the very forefront of this market.”

Wavywind® and Bubblebrush®

“The launch of our photobioreactors brought huge savings in production costs per kg of algal biomass. Costs that are significantly lower than those of conventional bag or bubble column systems. At the same time, increasing light levels and maintaining growth parameters at optimal value can reduce production costs even further.” The tubular PBRs convert light, nutrients and CO₂ via photosynthesis into biomass and oxygen, compatible with sunlight and artificial (LED) sources. Long tubular loops are possible because of the Wavywind® and Bubblebrush® technology, which makes upscaling significantly cheaper.

“Culture broth is continuously pumped into the system, while air is pumped in at a certain rate as well. That combination generates a wave that is pushed by a high-velocity air stream, known as the Wavywind®. When the wave travels along the tube, bubbles form, keeping the internal tube wall from fouling; Bubblebrush®.”

Lgem is very proud of the significant improvements that Wavywind® and Bubblebrush® technology bring to the algae cultivation process. “These improvements put the company’s patented systems on the next level compared to any others currently available in the market, as Lgem’s PBRs offer a smaller light path than conventional systems. It allows for cultivation at increased cell densities without losing productivity. Furthermore, as Lgem’s PBRs are closed systems, the culture is physically protected from contaminants.”

Lgem develops risk-free, stable and reliable systems with proven technology. The consistently high quality of our PBRs, due to industry-best mass transfer and smart hygienic design, is rivalled only by the ease of use, thanks to the simple and hassle-free operation with smart measurement and control. “In addition, it’s versatile, broadly applicable, proven effective under varying conditions and can be implemented for the cultivation and growth of any microalgae species, including the most fragile ones.”

Algae Hub

Lgem has the highest production standards, achieved with high-quality in-house engineering and production (following all relevant ISO standards). The newest Lgem industrial PBRs are entirely automated and easily integrated into a completely automated production facility with up-and downstream unit operations and climate-controlled greenhouse/buildings. The production capacity allows for short lead times worldwide, even for large projects.

“At Lgem, investment risk reduction is a crucial success factor for investors in a healthy algae industry. In our cutting-edge AlgaeHUB® facility, we offer customers the possibility to validate their business case on a commercially relevant scale before making significant investments. Because we understand: industrial production needs turnkey, fully automated solutions. Lgem is the one-stop-shop for the realization of algae production facilities.”

“We have expanded our production and showroom facility (8.000 m²) in De Kwakel, near Amsterdam Schiphol Airport, and have named it the AlgaeHUB®. Here, we can meet up, share knowledge and create a business. Clients can test the systems and the quality of the algae and have 100 percent reliable scale-up data. We’re also more than happy to open up our test facilities to research, universities and companies and grant them access to our lab, so that we can create an inspirational think-tank and cultivate innovation as well.”

Lgem’s PBRs are ready to be integrated into a fully automated workflow, combining the implementation with up-and downstream processes. Lgem offers tubular photobioreactors with volumes ranging from 25 to as much as 45,000 litres.