Lab Systems

Our lab systems are designed for high quality research projects and inoculum production.

At Lgem, we are dedicated to inspiring and informing researchers like you so together we can explore the limitless possibilities algae offer. Explore our latest innovations and high-quality solutions specifically designed to take your algae research to new heights. Whether you’re interested in biotechnology, sustainable nutrition, or eco-friendly materials, LGem is here to provide you with cutting-edge products and expertise.

How to Make Algae

Cultivation in a Closed System

To cultivate algae in a closed system, several important steps are required. Firstly, you need to select a suitable algae strain that thrives under the desired conditions. Next, you need to set up a bioreactor with control over temperature, lighting, and nutrients. It is essential to regularly provide the algae with a suitable nutrient solution, such as inorganic salts and CO2. By maintaining the right conditions, such as pH levels and oxygen levels, the algae can thrive and multiply, thus achieving sustainable algae production in a closed system.

To extract the algae from the closed system once you have reached the desired level of growth, there are several methods you can employ. A commonly used method is harvesting the algae through filtration. In this process, the algae-rich culture is passed through a fine-mesh filter, where the algae are collected, and the remaining liquid is discharged. After harvesting, the algae can be further processed for various applications, such as dietary supplements, biofuels, or the production of high-value chemicals.

1. Collect Data

Gather accurate data in high quality algae cultivation

A project in the AlgaeHUB® normally starts in the lab, where our scientists perform desk studies. The next step is the selection of a strain or screening potential candidates and cultivation conditions. Then we start experiments with a 5 liter lab system. After a successful experiment we will scale to a 25 liter system.

2. Optimize Processes

Test your research: experience our AlgaeHUB®

We offer research opportunities in our versatile and highly effective production systems. Our Pilot PhotoBioReactors (PBR’s) allow you to comprehensively evaluate and test your research.

3. Validate Cases

Ensure the reliability and accuracy of your findings

Over 18 photobioreactors and various upstream and downstream unit operations are available to accurately simulate a full-scale production facility. Therefore we validate cases in our Entos and Helios systems.

"Microalgae are a promising source for proteins and carbohydrates for the food and feed industry"

Sander Hazewinkel

CCO

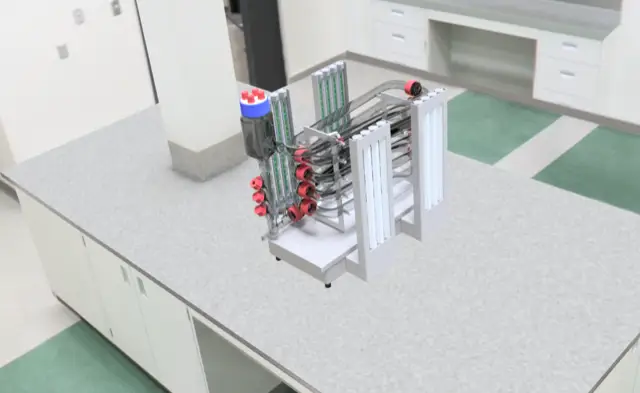

NEW: Lab-5

A 5-liter Bench-top System

Lgem introduces 5-liter Bench-top system, a new highly customizable entry level in algae cultivation

Lgem introduces its unique and innovative 5-liter benchtop system, catering to the entire algae cultivation supply chain, from research and startups to large-scale industrial production. The highly customizable 5L system, founded on the seed train methodology, offers an even lower entry level into algae cultivation, enabling researchers and startups to easily explore, initiate and optimize their algae cultivation.

Lgem's Lab Photobioreactor Systems

We proudly present our innovative technologies, the best in today's market, meeting all requirements of modern demand.

Lab-25

The Lgem Lab-25 tubular glass photobioreactor (PBR) is designed as a reliable research tool for producing ultra-clean inoculum material. The unit comprises one vertical tubular helix made from transparent glass pipes, a glass circulation vessel, instrumentation, and LED illumination. All are mounted on a moveable stainless steel (316) frame. The reactor helix and circulation vessel can be heat treated with 100°C/212°F hot water or steam. Sterilisation is a must-have for starter material production.

Lab-275

The Lgem Lab-275 tubular glass photobioreactor (PBR) is designed for research projects or as an inoculum production step for upscaling. The PBR has a stainless-steel box frame and a box circulations skid on height-adjustable feet for levelling. This makes the system very easy to move and relocate. The PBR is equipped with 4 LED panels on both sides. The circulation vessel, liquid circulation pump, valves, and fittings are heat tolerant, allowing pasteurisation with hot water (60-70°C). Pasteurisation provides for an exceptional hygiene level compared to any tubular system of this size on the market.

Knowledge

Our insights

The Seed Train

The seed train, or inoculation train, plays a crucial role in research and development by providing a continuous flow of high-quality starting cultures of micro-algae for use in photobioreactors (PBRs).

The best way to produce microalgae

Understanding the different technologies available to produce microalgae, and knowing the benefits and limitations of each technology, will provide clarity on what method and system will be most beneficial to get the outcome you need.

Algae Cultivation for Lab Use

How algae cultivation systems work, what the Lgem range of algae cultivation systems looks like, the advantages of Lgem algae cultivation systems, and algae cultivation applications.

Case Study

Successful step towards scale expansion Photanol thanks to Lgem’s 25L system

Photanol is dedicated to restoring balance on the planet by revolutionizing chemical production through circular practices. By optimizing cyanobacteria’s natural superpower of photosynthesis to absorb more CO2, adapting its metabolic pathways to produce a desired chemical. With the implementation of Lgem’s 25L bioreactor, Photanol has taken a significant leap towards scalability for industrial-sized production.

Challenge in Upscaling

To gain traction within the chemical production industry, Photanol must provide a viable alternative without compromising quality, ensuring that desired carbon compounds can be produced on a large scale and at a low cost.

Hayco Bloemen, Senior Process Development Engineer: “The developed bacteria multiplies itself. We are essentially optimizing our product like farmers to enable large-scale production.”

Technology partners

We pride ourselves in our partnerships, and together we can go to the next level.

Knowledge partners

We pride ourselves in our partnerships, and together we can go to the next level.