In microalgae biotechnology, photobioreactors (PBRs) are indispensable tools, enabling precise control over the cultivation environment to maximize algal growth and productivity. Addressing persistent challenges like biofilm formation, energy inefficiency, and uneven light distribution is critical for researchers exploring the potential of microalgae and producers scaling up for industrial applications. This article explores how innovative PBR technologies benefit the microalgae production community, offering solutions tailored to their needs.

Tackling biofilm formation and ensuring efficient cleaning

Biofilm formation is a common issue in PBR operations, leading to reduced light penetration, contamination risks, and increased maintenance. For microalgae producers, biofouling means costly interruptions and reduced yields; for researchers, biofilms can compromise experimental accuracy.

The advanced PBR design of Lgem mitigates biofouling using a two-phase gas-liquid flow. Elongated gas bubbles travel upwards through the reactor at twice the speed of the liquid, the so-called “WavyWind®”. The WavyWind® pushes along liquid slugs with tiny gas bubbles at the front, similar to a breaking wave. The turbulence from the liquid slugs prevents algal cells from settling on reactor walls, preventing biofilm development and improving cleaning. The tiny gas bubbles in the liquid slugs that scrub the reactor are also known as the “BubbleBrush®”. For end-users, the two-phase flow translates to less downtime, consistent performance, and reduces manual cleaning efforts.

Uniform light distribution in high-density cultures

In dense microalgae cultures, ensuring uniform light distribution is crucial to prevent shading and maximize photosynthetic efficiency. Uneven light exposure can hinder research outcomes and reduce productivity in large-scale operations.

The turbulent flow used in Lgem’s advanced PBR systems ensures that the microalgae culture is constantly mixed throughout the helix, exposing each cell to optimal light conditions. In addition, the elongated gas bubbles of the WavyWind® increase the surface area at which light can enter the culture, allowing more energy to be absorbed by the microalgae. The dynamic mixing and increased surface area are particularly advantageous for high-density cultures, allowing researchers to study dense populations accurately while producers can increase biomass production in space-constrained environments.

The WavyWind® and BubbleBrush® are Lgem’s patented technologies and represent significant advancements in microalgae cultivation, offering several advantages over conventional PBR systems. Thanks to the improved mixing and efficient light distribution, these innovations enable higher cell density cultivation without compromising productivity. Furthermore, the closed-system design of Lgem’s PBRs provides physical protection against contaminants, safeguarding cultures and ensuring consistent results.

Energy efficiency and sustainable operations

Energy consumption is a significant consideration for large-scale production of microalgae producers. Traditional systems often rely on liquid pumps for circulation and mixing, which can be energy-intensive to operate and are expensive to maintain. Lgem’s PBRs address this through gas-driven circulation and mixing, which require only air pumps or blowers and eliminate the need for liquid pumps. The reduced energy demand of Lgem’s PBRs is particularly beneficial for facilities aiming to integrate renewable energy sources. Potential surplus power generated by renewable energy sources can even be converted into biochemical energy by the microalgae, turning the PBR into a ‘biological battery’.

Expanding applications of algal biomass

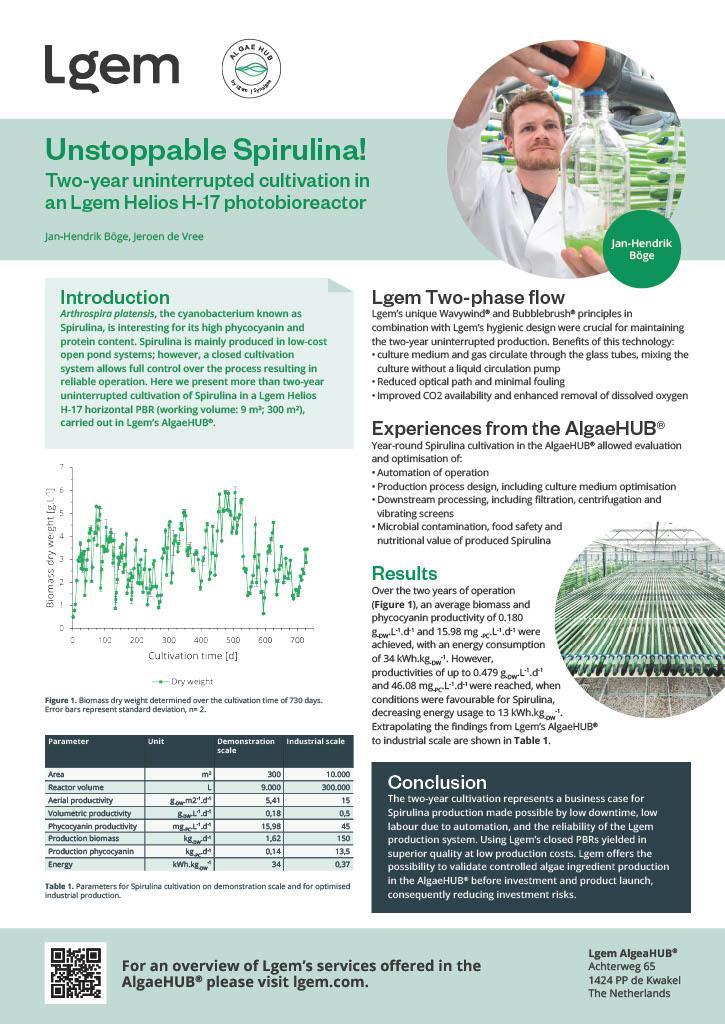

High-value compounds derived from microalgae, such as phycocyanin (used in nutraceuticals) and eicosapentaenoic acid (EPA, used in pharmaceuticals), represent significant opportunities. Producing these compounds requires precise control over cultivation parameters, including nutrient availability, light intensity, and temperature.

Our PBR systems offer this level of control, enabling researchers to fine-tune growth conditions for experimental purposes and producers to standardize processes for commercial production. Whether the goal is lipid-rich biomass for consumption or protein-dense strains for functional foods, these technologies provide the flexibility needed to meet diverse objectives

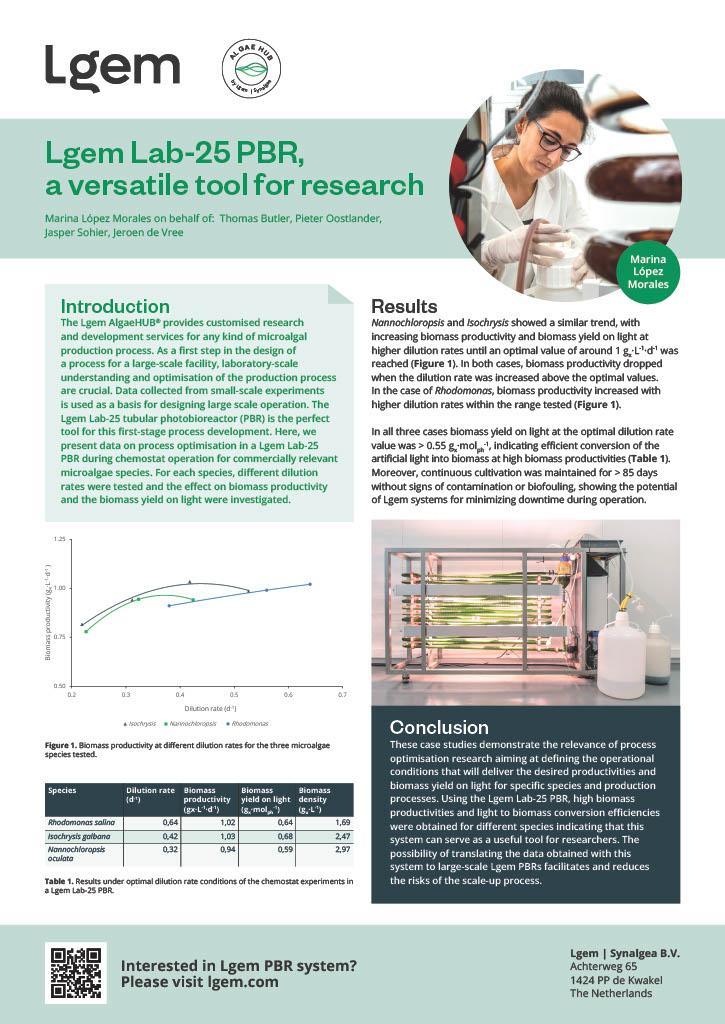

Overcoming challenges in scaling microalgae production

Scaling from laboratory experiments to industrial production introduces a host of technical and logistical challenges. For microalgae producers, this means maintaining biomass consistency in large culture volumes, while researchers often face the task of validating laboratory findings at scale.

Key solutions in algae production include:

Contamination Control: Automated monitoring and strict protocols minimize contamination risks, preserving culture integrity.

Biofouling Mitigation: The two-phase flow reduces fouling in critical areas, lowering maintenance demands.

Optimized Light Penetration: Effective mixing ensures even photon distribution throughout the culture, critical for scaling dense cultures. By adopting a phased approach, starting with laboratory trials and progressing through pilot and full-scale operations, researchers and producers can systematically optimize processes, reducing uncertainty and maximizing yields.

Lgem’s AlgaeHUB helps to overcome these challenges by providing a platform for researchers and producers to test and validate their processes on a commercially relevant scale before investing in a full-scale production facility. This multi-phased approach, starting with laboratory trials and progressing through pilot and full-scale operations at the AlgaeHUB, allows for systematic process optimization, reducing uncertainty and maximizing yields.

Future opportunities in microalgae production

The versatility of PBRs for the cultivation of microalgae opens avenues for innovative research and industrial applications. For researchers, exploring unconventional uses of algae, such as in biophotovoltaics or for bioremediation, highlights the untapped potential of these organisms. Similarly, advancements in real-time biochemical monitoring and novel light delivery technologies could enhance productivity for both experimental and industrial contexts.

For microalgae producers, addressing economic challenges or large-scale protein synthesis remains a priority. Further innovation in PBR cultivation strategies could make these applications more feasible, expanding the range of commercially viable products derived from algae.

Lgem’s PBR technologies are evolving to meet the complex demands of microalgae researchers and producers, providing robust solutions to persistent challenges like biofilm formation, energy inefficiency, and scalability. By enabling precise control over growth conditions and offering energy-efficient operation, Lgem’s PBRs support the production of high-value algal biomass for a range of applications. For those working in microalgae biotechnology, such advancements represent essential tools for driving innovation and achieving commercial success.