Lgem develops risk-free, stable and reliable systems with proven technology. The consistently high quality of our PBRs, due to industry-best mass transfer and clever hygienic design, is rivalled only by the ease of use, thanks to the simple and hassle-free operation with intelligent measurement and control. Our PBR solution are versatile, broadly applicable and proven effective under varying conditions. You can implement them for the cultivation of any microalgae species, including the most fragile ones.

The full range of Lgem

Of course, we could also share insights into the various smart solutions that complete a given setup of Lgem photobioreactors. You can read about Lgem’s innovative product development here. Now let’s take a look at the actual products.

For instance, the culture harvest unit automatically harvests and temporarily stores algae culture from the system. Or we could look at the clean water unit that stores up to 20 m3 of clean process water. It’s automatically circulated through a loop pipeline through a UVC-unit to maintain the quality, meticulously monitored by the Microalgae Production Control Computer, so we definitely need to tell you about our MPCC too. For now, though, we would like to address the various tubular glass photobioreactor systems.

We’d first like to explain the basic principles and design concepts of our PBR’s. After that, we can take a closer look at our current range of photobioreactors. We’ll start with the Lab-25 tubular glass PBR and the full-scale Pilot-6600, all the way to the Entos system for indoor industrial production with artificial illumination.

Unique photobioreactors

Lgem’s tubular photobioreactors use light, CO2 and fertilizers to cultivate micro-algae. We add nutritional elements like nitrogen, phosphorus and micro-elements to the water in which the algae are cultivated. Light converts CO2 into microalgal biomass and oxygen through the process of photosynthesis. As a light source, sunlight can be applied, but we offer, and in some situations indeed prefer, artificial (LED) light as well.

Actually, we are increasingly moving away from sunlight as a source of light due to its inherent production uncertainties and variations. We have designed our sizeable industrial standard to convert LED light into biomass as efficiently as possible under stable, optimized conditions. That approach has resulted in a higher yield as well as a better product. In addition, an artificial light source allows for a more condensed system design, reducing your spatial requirement. After all, you don’t have to prevent your system from being in the shade, as you have the freedom to place your light source where you want to have it.

We have designed our PBRs for cultivation at high cell densities. This is realised because the tubular shape has a relatively small layer where cells grows, so that the light absorption path is small, allowing for those high densities. Moreover, our PBRs are closed systems, neatly protecting the culture from contaminants.

After examining various algae production systems for many years, from plastic bags and bubble columns to PVC tubes, we’ve launched our glass tubular helix system. It offers extreme durability and a more simplified, cost-effective form of algae production.

Lgem PBRs consist of long tubular loops. You can easily configure large(r) systems by putting many tubular loops in parallel. You can therefore scale-up Lgem tubular systems to unit sizes up to more than 45,000 litres, which we will address later on. For now, let’s start small.

Our algae photobioreactor systems

Lgem’s tubular photobioreactors are ready to be integrated into a fully automated workflow, combining the implementation with up-and downstream processes. We’ll take a closer look at our products, ranging from Lgem LAB-25 to our Entos PBR.

Lgem Lab-25 photobioreactor

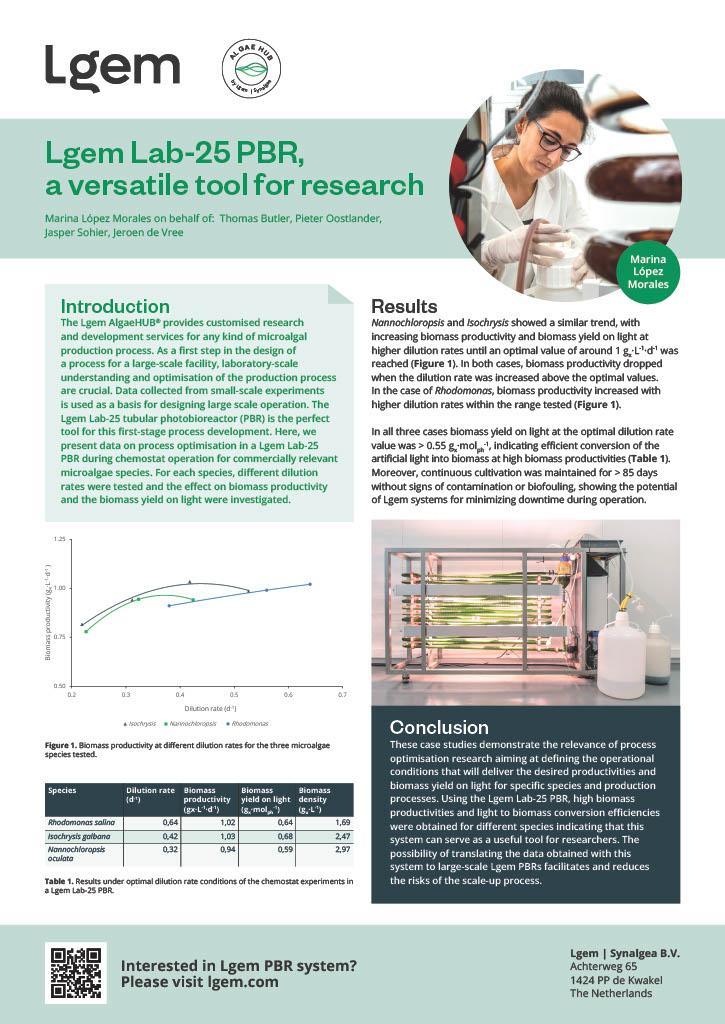

The Lgem Lab-25 tubular glass PBR is for laboratory research projects and the production of ultra-pure starter culture. You can reach high production rates and high biomass densities thanks to the 32 mm diameter tubes and excellent light intensities from the installed LEDs, offering up to 500 µmol/m2/s on the tubes’ surface.

The Lgem Lab-25 can be steam-sterilized before inoculation for very clean growth. The optional steam generator and all other features, such as the borosilicate glass, stainless steel frames and dimmable LED panels, are normally only be found in much more expensive systems from the lab equipment industry.

Lgem Lab-275 photobioreactor

Our Lgem Lab-275 PBR is explicitly designed for research projects or as an inoculation production step towards upscaling. The system comes in a stainless-steel box frame on wheels. We have equipped the Lgem Lab-275 with LED panels on both sides. The glass is constructed from borosilicate, while the circulation vessel is made from heat-tolerant PP semi translucent. It allows for pasteurization with hot water (60-70°), resulting in exceptional hygiene, especially when compared to any tubular system of this size currently on the market.

Lgem Lab-550 photobioreactor

We have designed the Lgem Lab-550 PBR for a research scale-up where space is limited, but more biomass is needed than can be provided with a Lgem Lab-25 or Lab-275 system.

We built the system on a skid and standardly fitted it with 12 LED panels. Like the Lgem Lab-275, this system can be pasteurized at 60-70°C, making it possible to easily switch between different algae species without the risk of cross-contamination.

Lgem Pilot-925 photobioreactor

The Pilot-925 is the first model in our Pilot series. We have specially designed this line for pilot-scale projects. The 925 consists of two skid-mounted units: a tank unit and a glass tubular helix unit with borosilicate glass tubes. Both units are transportable and you can easily connect them on-site. You can use the Lgem Pilot-925 outside or in a greenhouse for illumination by natural light. Additionally, you can also fit it with LED for climate rooms or warehouses.

Lgem Pilot-1700 photobioreactor

The second model in our Pilot series of tubular glass PBRs is designed for pilot-scale projects as well as inoculation production for larger production units. It is ideally suited for the validation of business cases. The Pilot-1700 consists of three skids: a tank unit and two glass tubular helices. However, assembly after transport is just as easy and intuitive as with our smaller Pilot model and does not require training. As with the 925-model, this PBR is suited for both natural light as well as LED illumination, while the modular setup allows for maximum flexibility if there is a need to relocate.

Lgem Pilot-3450 photobioreactor

Our Pilot-3450 is the first model in the series that uses an Industrial setup. The unit has a reactor volume of 3,450 litres and has two separate helices and one circulation skid. This means that the PBR isn’t completely skid-based. This way, it comes as a ready-to-set-up package that fits into a 40ft container, to be installed independently or with the assistance of our skilled installers. By doing so, the operating volume of the Pilot-1700 is doubled.

Lgem Pilot-6600 photobioreactor

We have built the Lgem Pilot-6600 similar to the Lgem Pilot-3450, but now with four separate helices on one circulation skid. This system also fits in one 40ft container for transport.

Lgem Helios photobioreactor

Lgem’s third in the series of proprietary PBRs for algae production is our Industrial line, made up of the Helios-25 and Helios-35 models. The Helios tubular glass photobioreactors are explicitly designed for industrial production using either sunlight or LED. It consists of two layers of 48 parallel borosilicate glass tubes. You can easily assemble them on-site with a variation in length up to 150m long.

The Helios can be delivered as a stand-alone solution with its own process computer or as a part of an integrated multi-unit production plant. The circulation consists of one transportable skid and tanks on frames that can easily be connected and to the tubular modules. The reactor volume is 25,000 litres to 35,000 litres, resulting in an operating volume of 16,000 – 31,000 litres. We offer Helios systems with double layers or even with 8 separate helices if you really want to go big.

Lgem Entos photobioreactor

We have built our Entos-45 PBR system with a reactor volume of 45 m³ or 45,000 litres, as you might have guessed from the name. That means you have an operating volume of 28,000 – 38,000 litres. We have optimised these systems for use in a controlled environment with artificial light. Whereas Helios consists of two horizontal layers, Entos has 12 parallel, vertical glass tubular modules. We have designed Entos for indoor industrial production with artificial illumination.